Friday, November 7, 2025

28.03 Le Studio automatise sa table de découpe Zünd pour renforcer sa compétitivité et conquérir de nouveaux marchés

2025SponsorsActualités des acteurs

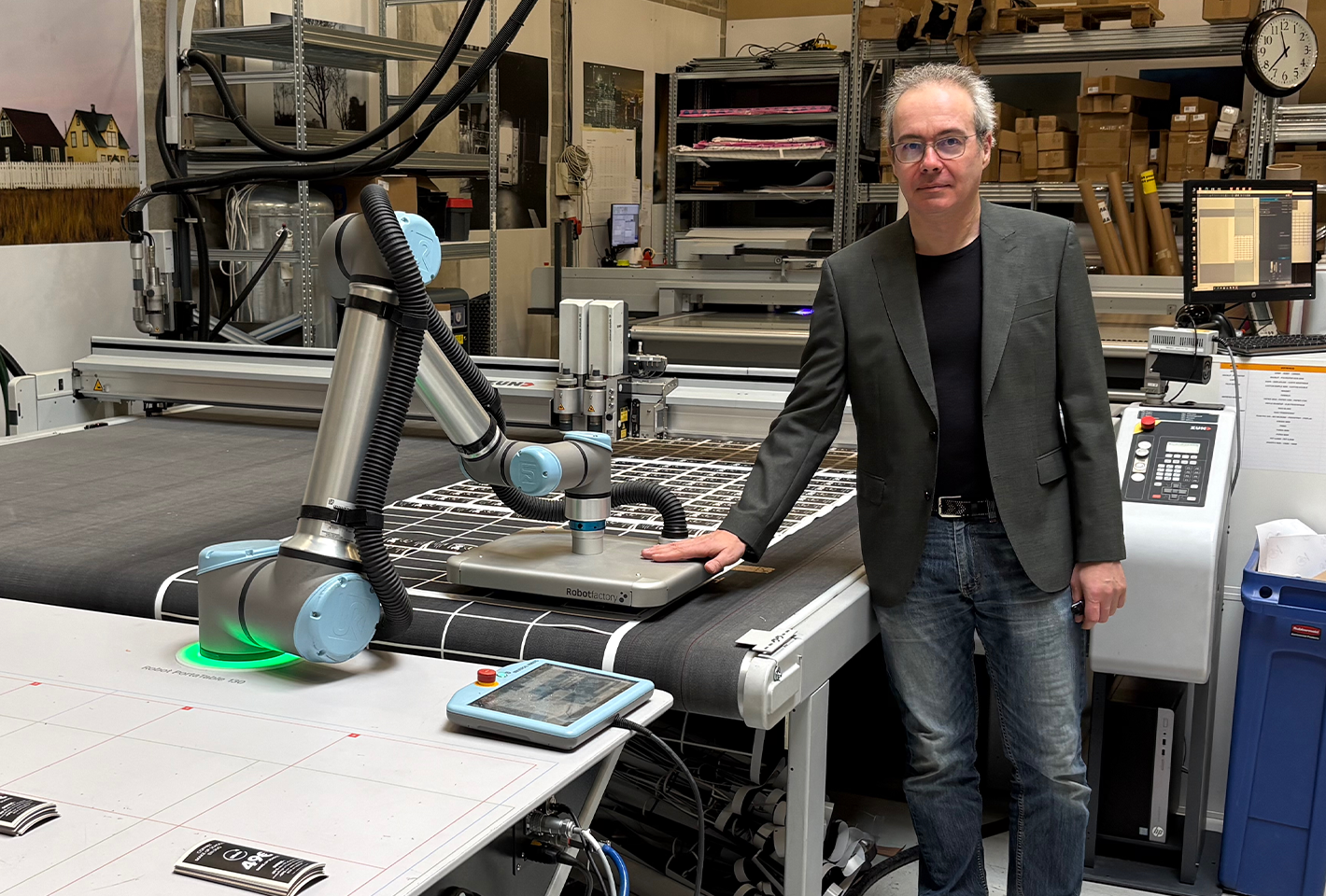

Vitry-sur-Seine, November 10, 2025 – In 2023, on March 28, Le Studio upgraded its production by automating its Zünd G3 2XL-1600 cutting table with an UR RobotFactory automatic unloading solution. This technological advancement now allows it to gain autonomy and productivity, while also accessing new markets.

Located in Saint-Denis, in the Paris region, 28.03 Le Studio is a digital printing company founded in 2008 by Emmanuel Branger. The company is equipped with a swissQprint large-format printing table, two Epson roll-to-roll plotters, and a Zünd G3 2XL-1600 cutting table . It serves a clientele of major retailers and brands in the food, cosmetics, and perfume sectors, producing point-of-sale displays and in-store decorations, as well as posters and promotional products (magnets, etc.).

RELIABILITY AND ROBUSTNESS

When it came to investing in a cutting table, Emmanuel Branger didn't hesitate to choose Zünd. " I looked at all the manufacturers in this market and quickly opted for Zünd. I chose the brand for its cutting precision, but also for its software and production workflow . The table and its software are easy to use and allow for quick training of new operators. The reputation of the Swiss manufacturer also played a role in our decision, " he confirms.

Emmanuel Branger also emphasizes the industrial dimension of the equipment:

A Zünd cutting table is truly an industrial-grade machine tool. It is therefore one of the few machines that can be financed over seven years. Other systems cannot be leased for such a long period .After a decade in production, the Zünd G3 2XL-1600 acquired by 28.03 Le Studio has fully proven its worth. " I can now confidently say that, regardless of the investment amount, a Zünd console is the most cost-effective piece of equipment on the market, thanks to its lifespan, reliability, and near-absence of breakdowns, provided it is under a maintenance contract. This contract guarantees continuous production."

A FULLY AUTOMATED PRODUCTION

The Portatable 130 automatic unloading robot was developed specifically for Zünd tables by the Danish distributor UR Robotfactory. "This robot immediately caught my attention. We were the first in the world to be equipped with it, even before it was commercially available," recalls Mr. Branger.

This system is positioned on a table at the end of the Zünd cutting table's cutting area. An articulated arm carries a suction cup gripping system capable of grasping elements of any shape. The system can therefore pick up the cut elements wherever they are on the cutting area, stack them ready for packaging, or sort the elements into separate bins. The robot's software interfaces directly with the table's software.

No programming is required for the robot, which can therefore begin its work as soon as it is connected to the table. " The robot works more slowly than an operator, but ultimately handles a significantly larger workload ," explains Emmanuel Branger. " By taking on repetitive tasks, it frees up an operator who can then dedicate themselves to higher value-added tasks. In a context of operator shortages, this is a real advantage."

Investing in a robot has also opened up new possibilities for the company.

“The robot works in the background, 24/7, day and night, including weekends ,” continues Emmanuel Branger. “ As a result, I’m now able to position myself in markets with quantities I wouldn’t be able to handle otherwise. The robot has allowed me to scale up on jobs that were previously beyond my reach. And orders arriving in the middle of the afternoon with delivery the following morning are now possible.”

A SERVICE DIMENSION TO CONSIDER

Such a production approach is only feasible with strong support from the manufacturer, capable of assisting the company even during the phases when the machines are running without human presence in the workshop. " Choosing a cutting table or a handling robot is first and foremost about connecting with people ," emphasizes Emmanuel Branger. " With Zünd, trust is established very early on, from the very first discussions. During demonstrations, the technicians demonstrate a perfect command of their equipment and a genuine understanding of the context of use, from the essential requirements to the production constraints. This technical expertise is complemented by a particularly well-established customer service department. Responsiveness, attentiveness, and efficiency characterize a team capable of providing concrete solutions for every need ."

More than just a simple equipment purchase, it's a lasting partnership that's being built. " We've never been left without an answer, which has allowed us to develop our skills over time ," concludes Emmanuel Branger.

AND TOMORROW?

28.03 The Studio now plans to invest in a second Zünd cutting table:

“I’m planning to acquire a newer generation table in a smaller format by 2026 and pair it with my current robot,” explains Emmanuel Branger . “The robot picks up materials across a width of 160 cm. The table I currently use is 270 cm wide. By combining the robot with a smaller table, I’ll optimize production. And I’ll have my existing table available in a larger format to handle exceptional jobs or urgent orders, without having to interrupt production on the other table. The market is moving towards ever-shorter lead times; we have to anticipate this to remain competitive.”